Effortless integration with compact I/O and powerful edge computing.

RIO M1 & M2

What is groov RIO M1 & M2 The Future of Remote I/O to Edge Intelligence

Discover the future of I/O

Universal remote I/O with Edge-ready intelligence

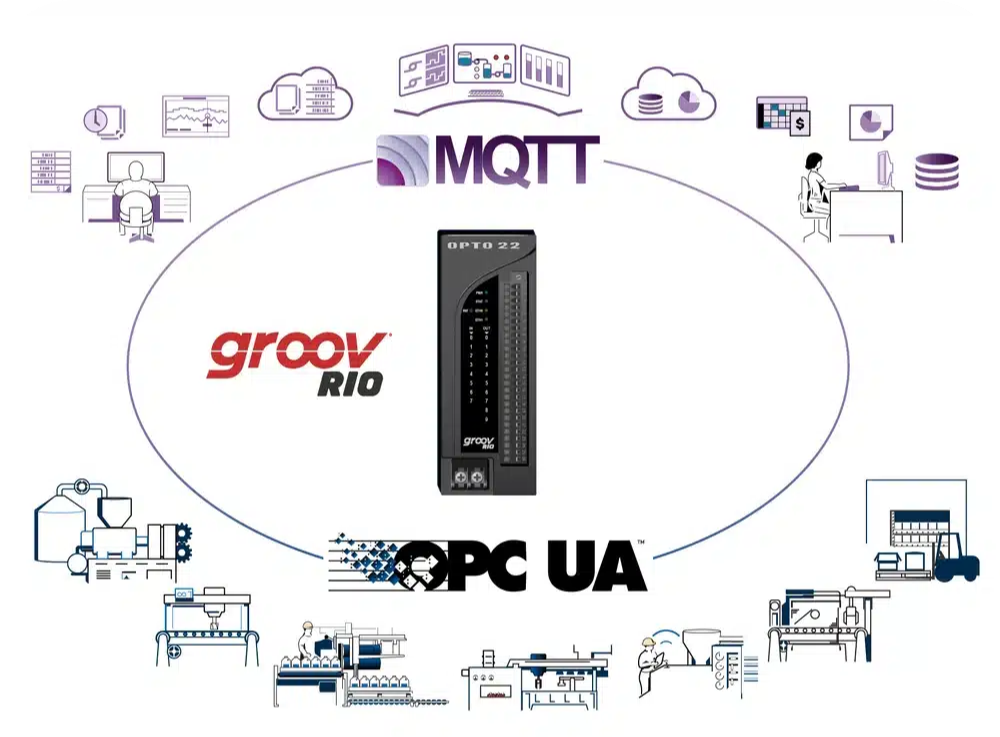

The groov RIO M1 and M2 modules offer software-configurable, multi-signal I/O in a compact, industrial form—eliminating the need for custom wiring and multiple I/O cards. With built-in edge processing, dual Ethernet ports, and native protocol support, groov RIO is designed to deploy fast, scale easily, and integrate seamlessly into both traditional and IIoT systems.

Two models, flexible options for control and integration

Choose the M1 for standalone I/O and edge data publishing, or step up to the M2 for full control with PAC Control Runtime and certified Ignition Edge support. Both devices come ready with built-in Node-RED, Python, and REST APIs for edge automation and data handling.

Smarter I/O for system integrators, OEMs, and end users

groov RIO’s software-defined I/O allows one device to handle multiple signal types — from digital and analog to thermocouples and RTDs. Integrators save on design and wiring time, OEMs standardise builds, and engineers gain local data control and cloud connectivity in one drop-in unit.

No racks. No PLCs. No licensing fees.

With universal I/O, secure networking, and open protocols, groov RIO M1 and M2 remove traditional automation barriers. Get real-time control and communication with zero additional software licences, central processors, or proprietary lock-ins.

Features

Features of Groov RIO M1 & M2

Software-configurable for analog, digital, temperature, and relay I/O.

Supports Modbus/TCP, MQTT, OPC UA, SNMP, and REST API for seamless industrial integration.

Runs local logic, data processing, and automation workflows without a PLC.

TLS encryption, user authentication, and VPN support ensure data security.

Supports daisy-chaining, separate control/data networks, and easy expansion.

Easily connects to AWS, Azure, Google Cloud, Ignition, and SCADA systems.

Case Studies

How Point Energy Partners Improved Operational Efficiency By Saving Annually

COMPARE

Compare the groov RIO M1 & M2

RIO M1

An industrial controller with real-time control, edge computing, and secure connectivity.

RIO M2

A high-performance controller with faster processing and expanded connectivity.

RIO EMU

A compact energy monitoring unit with real-time data logging.

2GB memory for control, connectivity, and data handling.

4GB memory for enhanced performance, ideal for more demanding applications, including Ignition Edge 8.

4GB memory for enhanced performance, ideal for more demanding applications, including Ignition Edge 8.

Standard memory for control, connectivity, and data handling.

Increased memory for enhanced performance, ideal for more demanding applications, including Ignition Edge 8.

Increased memory for enhanced performance, ideal for more demanding applications, including Ignition Edge 8.

Supports PAC Control, CODESYS, Node-RED, and groov Manage; optional Ignition Edge.

Supports PAC Control, CODESYS, Node-RED, and groov Manage; optional Ignition Edge.

Supports PAC Control, CODESYS, Node-RED, and groov Manage; optional Ignition Edge.

Dual Ethernet interfaces, built-in firewall, user authentication, no default passwords, MQTT/Sparkplug, and OPC UA support.

Dual Ethernet interfaces, built-in firewall, user authentication, no default passwords, MQTT/Sparkplug, and OPC UA support.

Dual Ethernet interfaces, built-in firewall, user authentication, no default passwords, MQTT/Sparkplug, and OPC UA support.

RESOURCES

Resources for groov RIO M1 & M2

groov EPIC, groov RIO, MQTT

Guide to Networking groov Products

Discover how to network groov EPIC and RIO — read

groov RIO, groov RIO EMU, groov RIO M1 & M2, groov RIO Security, Opto 22

groov RIO Data Sheet

This data sheet outlines technical specifications, I/O capabilities, supported protocols,

groov RIO, groov RIO EMU, Opto 22

groov RIO EMU Brochure

Get real-time insight into your energy use with groov RIO

groov EPIC, groov RIO, Opto 22, Reports

I/O for the IIoT

See how Edge I/O creates a simpler way to meet

groov EPIC, groov EPIC Security, groov RIO, groov RIO EMU, groov RIO Security, Opto 22

groov EPIC and groov RIO Cybersecurity Design and Best Practices

groov EPIC and groov RIO are built from the ground

groov RIO, groov RIO EMU, Opto 22

groov RIO Energy Monitoring Unit Data Sheet

Technical specifications for the groov RIO EMU, including input compatibility,

FAQ

Frequently Asked Questions

The groov RIO M1 (GRV-R7-MM1001-10) is a remote I/O module with built-in edge processing tools like Node-RED and Python, while the M2 (GRV-R7-MM2001-1) includes additional features such as PAC Control Runtime and Ignition Edge®, enabling full control capabilities and HMI support.

Universal I/O means each of the 8 channels on groov RIO M1 and M2 can be independently configured for digital, analog, thermocouple, RTD, or frequency input/output — eliminating the need for dedicated I/O modules and simplifying hardware design.

The groov RIO M2 can function as a standalone controller thanks to PAC Control Runtime. It runs control strategies locally, making it ideal for small automation tasks without requiring a separate PLC or PAC.

Both groov RIO M1 and M2 support native protocols including MQTT (with Sparkplug B), Modbus/TCP, OPC UA, and RESTful APIs — enabling seamless integration with SCADA systems, databases, and cloud platforms.

Yes. Node-RED is pre-installed on both groov RIO M1 and M2, allowing users to create powerful logic flows, data transformations, and system integrations using a visual drag-and-drop interface.

groov RIO devices support:

•Node-RED for flow programming

•Python 3 for scripting

•PAC Control (M2 only) for full IEC 61131-3 compatible control logic

These tools provide flexibility for developers, integrators, and OEMs.

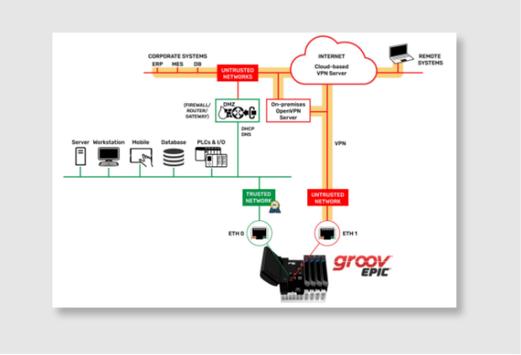

groov RIO offers dual Ethernet ports (switchable or segmented), VLAN support, an integrated firewall, user-based authentication, and VPN support, making it secure for both internal and remote deployments.

No. All necessary tools — including protocol support, Node-RED, and PAC Control (for M2) — are included with the hardware. There are no recurring licence fees, making it a cost-effective, scalable solution.

groov RIO M1 and M2 are ideal for:

•Remote I/O expansion

•Edge computing

•IIoT gateway functions

•Standalone control (M2)

•Cloud integration and protocol bridging

They suit industries such as manufacturing, utilities, water treatment, and machine automation.