Modernising control systems with open, agile, and hardware-independent automation.

OVERVIEW

What is Codesys?

Why Codesys?

The Limitations of Traditional Automation Platforms

CODESYS runs on diverse hardware, giving you choice and control.

Built on IEC 61131-3, supporting multiple programming languages.

Reduces capital and ongoing costs with open, scalable tools.

The Freedom of CODESYS

Tied to one vendor’s hardware and software, limiting flexibility.

Upgrades and integrations are harder and more costly.

Proprietary tools drive up setup and maintenance costs.

Benefits

Codesys Benefits

Smarter logic. Greater flexibility. All in one platform.

Accelerated Development & Deployment

CODESYS streamlines the entire engineering process by combining PLC programming, simulation, HMI design, motion control, and configuration tools into one unified environment. Engineers can develop and test applications offline with built-in simulators, reducing hardware dependency during prototyping. This results in faster commissioning, fewer errors in deployment, and a significant reduction in time-to-market.

Scalable from Edge to Enterprise

Whether you’re programming a compact controller for a single machine or orchestrating a large-scale distributed automation system, CODESYS adapts to your scale. The same codebase, tools, and libraries can be used across devices of varying complexity—from embedded modules to high-performance IPCs—ensuring consistency across your automation architecture. This scalability is ideal for companies planning growth or managing a variety of system sizes.

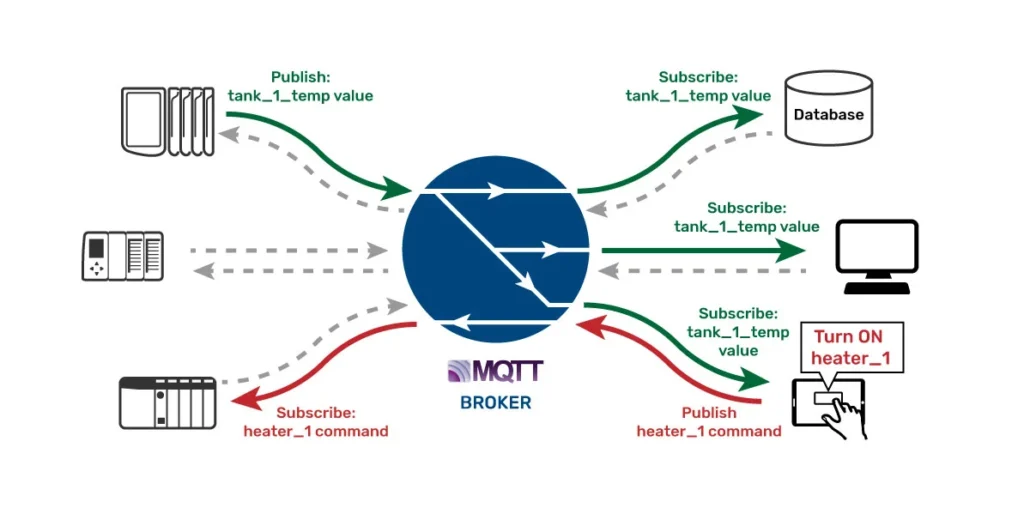

Seamless IIoT & Cloud Integration

CODESYS is built with Industry 4.0 in mind. With native support for modern protocols like MQTT, OPC UA, and REST APIs, it allows for secure and efficient data exchange between edge devices, cloud platforms (AWS, Azure, etc.), and SCADA systems. This makes it ideal for applications requiring real-time remote monitoring, predictive maintenance, and integration with MES or ERP systems.

Platform Flexibility = Long-Term Stability

CODESYS enables you to break free from restrictive proprietary ecosystems. By supporting a wide range of third-party hardware, it gives you the freedom to pivot, expand, or replace hardware without being forced to abandon your existing software investments. This reduces risk, improves purchasing flexibility, and protects your project from supply chain disruptions and vendor-specific end-of-life issues.

Features

Codesys Features

Use Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Sequential Function Chart (SFC), and Instruction List (IL)—all within one IDE.

Design HMIs in the same environment and deploy them as browser-based interfaces accessible via any modern device.

Run and test control logic on your PC before deploying, using live variables, breakpoints, and trace diagnostics.

Native support for OPC UA, MQTT, Modbus, EtherCAT, CANopen, EtherNet/IP, and PROFINET allows seamless connectivity in mixed environments.

Create reusable libraries, function blocks, and templates for streamlined team development and rapid deployment.

Certified for SIL2/SIL3 safety applications and capable of redundancy configurations—meeting industrial demands for reliability and compliance.

Case Studies

How Gebhardt Transformed 900+ PLCs with CODESYS Automation Server

Gebhardt Intralogistics Group transformed their warehouse operations with the CODESYS Automation Server, streamlining PLC management and eliminating on-site update delays. Discover how they scaled faster, worked smarter, and set a new benchmark for industrial automation.

RESOURCES

Codesys Resources

Codesys

CODESYS Brochure for Device Manufacturers

CODESYS gives device manufacturers a flexible, hardware-independent platform for IEC

Codesys

Codesys

Learn more about CODESYS—an industry-standard programming environment built into groov

Codesys

CODESYS Security Whitepaper

CODESYS includes built-in security features like encrypted communication and user

Codesys

CODESYS Brochure for Users

CODESYS empowers users with a unified, hardware-independent platform for IEC

Codesys, groov EPIC, groov RIO, Opto 22

groov RIO vs groov EPIC

A Comprehensive Comparison for Industrial Automation Solutions

Videos

Codesys Videos

Whats New in CODESYS? Qtr. 1 2025

See Why CODESYS Virtual Control Scales Smarter

CODESYS Licensing: A Quick Overview

What is Codesys?

FAQ

Codesys Frequently Asked Questions

Is CODESYS free to use?

The CODESYS Development System (IDE) is free to download and use for development and simulation. However, runtime licenses must be purchased for deployment on target hardware, and some features (e.g. Safety, Redundancy) require additional licensing.

What hardware is compatible with CODESYS?

CODESYS supports a wide range of industrial hardware, including PLCs, IPCs, and embedded systems from leading manufacturers. Notably, Opto 22’s groov EPIC® and groov RIO® platforms come with built-in support for CODESYS, offering a powerful, flexible foundation for edge control and industrial automation. These systems combine I/O, networking, and control in one compact unit—ideal for CODESYS-based applications in smart manufacturing, IIoT, and remote monitoring.

Can CODESYS be used for IIoT and cloud integration?

Yes. CODESYS supports modern protocols like MQTT, OPC UA, and REST API, enabling real-time data communication with cloud platforms and SCADA systems. It’s suitable for Industry 4.0, edge computing, and remote monitoring applications.

Is CODESYS suitable for safety and mission-critical systems?

Yes, CODESYS offers certified extensions for SIL2/SIL3 applications through CODESYS Safety and supports redundancy configurations, making it suitable for high-reliability and safety-critical environments.

Can I simulate and test my CODESYS application without hardware?

Yes. The CODESYS Development System includes a built-in software-based PLC for simulation and offline debugging. This allows you to write, compile, and test your control logic before deploying it to live hardware—saving time and reducing commissioning risks.

How often is CODESYS updated?

CODESYS is actively maintained by 3S-Smart Software Solutions with frequent updates that include new features, security enhancements, and expanded device support. Updates are published regularly and reflect both user feedback and evolving industry standards.

Take The Next Step

Connect With a Sales Specialist

Get expert guidance tailored to your automation goals. Talk to a Binford Tech specialist and take the next step with confidence.

Get Engineering Support With Miltek

Need tailored technical advice? Speak with a Miltek engineer to explore solutions built for performance and precision. Miltek is our trusted engineering partner.